|

|

Copyright 2002 Michael A. Covington.

Please link to this page rather than reproducing copies of it.This page is not in any way connected with or endorsed by Eastman Kodak Company or any other photographic manufacturer. Many of the product names that appear on this page are registered trademarks of their respective owners.

NOTE ADDED 2006: I am no longer doing much film photography and am no longer actively updating this page. I will make corrections as needed to keep its contents accurate, but I am no longer soliciting further information about this developer. Thank you for your interest!

About Xtol

Introduced in 1996, Xtol (pronounced EX-tall) may be the only genuinely new black-and-white film developer invented since Kodak HC-110 thirty years earlier.Xtol is one of the few developers that do not contain hydroquinone. It uses derivatives of ascorbic acid (vitamin C) and Phenidone as developing agents. Claimed advantages include low toxicity (important for environmental reasons as well as occupational safety), easy mixing (but see below), and an unusual combination of fine grain with high film speed (true shadow speed, not just push-processing).

Other useful web pages about Xtol include:

(I cannot promise that all these links will stay in place, of course.)

- Kodak's Xtol data sheet in English in German in Spanish

- Jobo's bulletin on using Xtol in rotary processors

That Funny Name

If you do a web search you will quickly learn that in mathematical software, xtol often means "tolerance on the x-axis," completely unrelated to the name of this product as far as I know. Xtol is also a word in Zapotec, a Native American language, but I don't know what it means.Most likely, the name of the developer is derived from X (an element in many Kodak trademarks) and -tol as in Dektol, Versatol (Kodak developers). Or it may be that Kodak has highly extolled this product!

Xtol's Controversial Start

Almost as soon as Xtol came out, photographers in Internet forums started reporting problems with it. It was hard to dissolve in water and would sometimes lose its strength suddenly without turning brown or giving any other warning.Simultaneously, other photographers got excellent results and found that Xtol was everything Kodak claimed for it.

Users report that the failures are sudden. The developer does not gradually get weaker in storage. Instead, one day it works and the next day it doesn't. Further, most of the failure reports seem to involve Kodak T-Max 100 film.

By 2001, Kodak had tracked the problem to two sources.

(1) The small packets of powder, to make 1 liter of solution, were not adequately sealed to keep out air and humidity - or perhaps there was just too little powder in them, in proportion to the air that would inevitably get in. As a result, the powder would cake and become hard to dissolve, and the life of the developer would also be impaired.

(2) Xtol performed poorly at high dilutions (1:2, 1:3) in water of varying quality.

After making several attempts to improve the 1-liter packets, Kodak finally discontinued them altogether; the smallest size of Xtol that you can get is now 5 liters. Also, Kodak stopped publishing developing times for Xtol at dilutions higher than 1:1 (but see below).

Update: As of March 2002, Xtol is simply disappearing from the shelves of many camera stores that stock other darkroom supplies. Apparently, by discontinuing the 1-liter packet, Kodak effectively took Xtol out of the amateur and small-darkroom market; they continue to promote it in 5- and 50-liter packets for use in processing machines.

Mixing and Keeping Xtol

Xtol is supplied as a two-part powder. My experience with Xtol has been with the now-discontinued 1-liter packets, and I understand that the 5-liter packets are much easier to work with.For reproducibility and good keeping properties, I prefer to work with distilled water even though Kodak says tap water is safe.

Mixing from 1-Liter Packets

I found it best to start by warming some distilled water to 85°F in a microwave oven (or warming a small portion of the water to a much higher temperature and then mixing it). I followed Kodak's instructions, allowing plenty of time for Part A to dissolve before adding Part B. Often I could not get the last traces of powder to dissolve, so I filtered the solution after mixing. As long as at least 98% of the powder dissolves, the developer works fine.On rec.photo.darkroom, Jon Porter says he gets the best reliability by dissolving Packet A at 95 F, then letting the solution stand for 15 minutes before adding Packet B.

Mixing from 5-Liter Packets

Reportedly, the 5-liter packets are much easier to dissolve, and I have heard of people dissolving the whole package in 2 liters of water, then diluting it.

Ordinarily, however, you will need 5 liters (1.3 gallons) of distilled water and a very clean 2-gallon bucket to do the mixing in, plus five 1-liter bottles in which to store the prepared developer.

The Container Store sells a 107-ounce (3-liter) French canning jar made of glass that looks handy for mixing and storing a 5-liter packet of Xtol at double strength. (I think I've seen a 5-liter version of this container in their Atlanta store, but call first to confirm availability.) Avoid plastic containers for long-term storage of developer.

Keeping Properties

In a full, tightly capped brown glass bottle, Xtol stock solution will keep for more than 8 months (confirmed by my experience). To get Xtol or any other developer to last, you must protect it from air. Here are three tips:The first two of these are based on others' published experiments (from where, I don't remember; probably Photo Techniques). The third is my tried-and-true technique.

- Use a glass bottle, not plastic.

- Put Saran wrap under the bottle cap to make it seal more tightly.

- If the bottle is not full, use "Dust-Off" gas to displace the air in it before putting the cap on.

Making Sure Your Xtol Hasn't Gone Bad

Because Xtol does not turn brown when oxidized, you can't tell whether it has gotten too old by just looking at it. Here are two simple tests you can use instead.

Clip test

This can also be used to determine an approximate developing time for an unfamiliar kind of film.Cut off a small piece of the film and develop it in full room light, using the development time you consider most likely to be correct. Wash it in water, fix it in fixer, wash it again, and let it dry.

Then compare your sample to the fully exposed end of a correctly developed roll of the same or similar film. Your sample should be almost but not quite black; strong lights should be visible through it. If it's not very dark, increase development or mix fresh developer; if it's pitch-black, use a shorter developing time.

Paper test

This is a very quick way to determine that your Xtol stock solution still works. You'll need a small scrap of photographic paper that doesn't have a developing agent incorporated; I use Ilford Multigrade IV RC, but many others work just as well. Try the test with a known good sample of developer before relying on it.To perform the test, expose the paper to full room light (white light, not safelight) and put a drop of Xtol on it. Then, 30 seconds later, put another drop of Xtol on it in a different place. After 30 more seconds, rinse the paper under running water and put it into the fixer, then wash and dry as usual. The first spot should be dark gray, and the second one, medium gray. After fixing they will be quite warm-toned.

An Alternative to Xtol?

Because the 1-liter packets have been discontinued, Xtol is not as convenient to use as it used to be. Many photographers are switching to Ilford Ilfotec DD-X as an alternative. Reportedly, Ilfotec DD-X has many of the same desirable properties - fine grain, full speed, and good shadow detail without excessive highlight density. It is a conventional formula using Phenidone and hydroquinone as its developing agents. Kodak T-Max Developer has a somewhat similar formula but is much more active, producing excessive highlight density when films are slightly overdeveloped.Like Kodak HC-110, Ilfotec DD-X is a glycol-based liquid concentrate with excellent keeping properties. (It is not as syrupy as HC-110.) At the recommended 1:4 dilution, Ilfotec DD-X is relatively expensive, but some photographers are using it diluted 1:9 with development times about 70% longer.

I'm going by published reports here; I haven't tried Ilfotec DD-X myself.

Another Alternative -- Paterson FX-50

If you can't get Xtol, try Paterson's new FX-50 as a substitute. It has a similar formula but is prepared as two stock solutions that keep for a very long time and are mixed together just before use.I have not yet tried it or heard much about it, except that it apparently works reliably.

Development Times

I always use Xtol as a "one-shot" developer, with no attempt to reuse it. Kodak does, however, give recommendations for reusing the developer and for using it as its own replenisher.Current Recommendations

Kodak's published tables for undiluted Xtol and Xtol 1:1 give recommended developing times for Kodak, Ilford, Fuji, and Agfa black-and-white films. A more comprehensive table of developing times, comprising many films and developers, is available at www.digitaltruth.com.Some of the most-used developing times for 35-mm film are the following. They assume agitation for 5 seconds every 30 seconds.

Important note: In 2002, Kodak changed its manufacturing processes for a number of films. Although the photographic characteristics were not affected, development times have changed. The new films have new designations, such as 400TX instead of TX.

For Xtol, the changes were slight (typically a 15% increase for faster films, no change for slower films). That is why no times for the newer films are listed below. For more information see Kodak's press release, Kodak's revised development times, and the general information available on www.kodak.com.

Film Speed Dilution Time Time (68 F) (75 F) (20 C) (24 C) Kodak Tri-X Pan 400 Undiluted 7 min 5 min 1600 Undiluted 9 min 6.5 min Kodak Tri-X Pan 400 1:1 9 min 7 min 1600 1:1 12 min 9 min Kodak T-Max 100 100 Undiluted 7 min 5 min Kodak T-Max 100 100 1:1 9 min 7 min Kodak T-Max 400 400 Undiluted 6.5 min 4.5 min 1600 Undiluted 8.5 min 6 min Kodak T-Max 400 400 1:1 9 min 7 min 1600 1:1 11 min 8.5 min Agfapan APX 25 25 Undiluted 5 min 3 min Agfapan APX 25 25 1:1 6 min 4.5 min Fuji Neopan 400 400 Undiluted 8 min 6 min Fuji Neopan 400 400 1:1 10 min 7 min Ilford Pan F Plus 50 Undiluted 7 min 5 min Ilford Pan F Plus 50 1:1 8 min 5 min Ilford FP4 Plus 125 Undiluted 8 min 5 min Ilford FP4 Plus 125 1:1 10 min 6.5 min Ilford HP5 Plus 400 Undiluted 8.5 min 6 min 1600 Undiluted 13 min 9 min Ilford HP5 Plus 400 1:1 12 min 7.5 min 1600 1:1 18 min 12 minThese are from the Kodak Xtol data sheet, September 2000, but have been rounded to the nearest half-minute. Do your own experiments to refine your development times. Note in particular that correctly developed T-Max films look somewhat less dense than correctly developed Tri-X Pan.Older Recommendations for Xtol 1:2 and 1:3

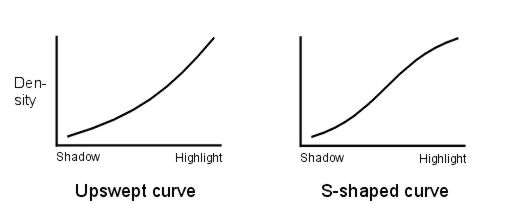

Kodak no longer recommends using Xtol at dilutions higher than 1:1, but many photographers, working carefully with fresh Xtol, continue to get good results. At high dilutions you can expect greater sharpness, more of an S-shaped curve, slightly higher film speed, and slightly coarser grain.It takes 100 mL of Xtol stock solution to develop a roll of 35-mm or 120 film, regardless of the size of the tank. Thus, when working with Xtol 1:3, you must mix up 400 mL of solution (100 mL Xtol + 300 mL water) and use a two-reel tank to develop a single roll.

Fortunately, as this is written (February 2001), the diluted Xtol development times are still on Kodak's German Xtol data sheet ("Entwicklung in der Dose mit frischem, verdünntem Entwickler"). Here are some useful ones (again assuming agitation for 5 seconds every 30 seconds).

Film Speed Dilution Time Time (68 F) (75 F) (20 C) (24 C) Kodak Tri-X Pan 400 1:2 10.5 min 8.5 min (TX, not 400TX) 1600 1:2 14.5 min 11 min Kodak Tri-X Pan 400 1:3 12.5 min 9.5 min (TX, not 400TX) 1600 1:3 16.5 min 13 min Kodak T-Max 100 100 1:2 12.5 min 9.5 min Kodak T-Max 100 100 1:3 16 min 12.5 min Kodak T-Max 400 400 1:2 10.5 min 8.5 min 1600 1:2 14 min 11 min Kodak T-Max 400 400 1:3 13.5 min 11 min 1600 1:3 17 min 14 min Agfapan APX 25 25 1:2 9 min 7 min Agfapan APX 25 25 1:3 12 min 9 min Fuji Neopan 400 400 1:2 12.5 min 9 min Fuji Neopan 400 400 1:3 16 min 11.5 min Ilford Pan F Plus 50 1:2 10 min 7 min Ilford Pan F Plus 50 1:3 12 min 8.5 min Ilford FP4 Plus 125 1:2 11.5 min 8 min Ilford FP4 Plus 125 1:3 15 min 9.5 min Ilford HP5 Plus 400 1:2 15.5 min 10.5 min 1600 1:2 21 min 15 minTechnical Pan in Xtol

Kodak Technical Pan Film can be developed in highly diluted Xtol. Here are Kodak's recommendations (no longer in the current data sheet, but apparently usable if you work carefully):KODAK TECHNICAL PAN FILM Contrast Speed Developer Time Index (EI) (70 F) (21 C) 0.60 4 Xtol 1:2 6 min 0.60 8 Xtol 1:3 8 min 0.60 12.5 Xtol 1:4 10.5 min 0.60 25 Xtol 1:5 12.5 minRemember to use 100 mL of Xtol stock solution per roll developed. This means that when developing a single roll in Xtol 1:5, you must use 600 mL of diluted developer in a 5-reel tank.On the whole, Kodak Technidol developer is probably a better bet.

Converting to Other Temperatures

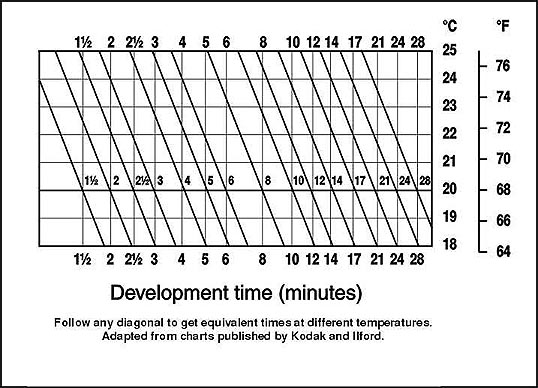

You can compensate for small changes in development temperature (over the range 66-75°F, 19-25°C) by changing the development time.To adjust the development time for a temperature other than the one specified, use these formulae:

On some calculators EXP x is called ex. New time = Old time × exp(-0.081 × (New temp °C - Old temp °C))

New time = Old time × exp(-0.045 × (New temp °F - Old temp °F))

Though derived from published data about HC-110, these formulae are also approximately correct for most other developers. You can also use this chart:

Developer Characteristics

Xtol is a solvent developer, which means it produces fine grain by allowing silver to redistribute during development. This solvent action slightly reduces resolving power. For less solvent action but slightly higher film speed, work with Xtol 1:1 rather than undiluted.In spite of its solvent action, Kodak claims that Xtol produces relatively high acutance (sharpness) compared to other developers, with "enlargeability of negatives 10 percent greater with equivalent sharpness and grain" (presumably compared to D-76).

Xtol produces high film speed - that is, the true film speed, as measured by shadow detail, is about 1/3 stop higher than with D-76 or other standard developers.

This is true even when the film is developed to low contrast. It is not the same as push-processing, which is a way of raising speed in the midtones but not the shadows through overdevelopment. Nonetheless, Xtol is an excellent developer for pushing; you might as well have both benefits at once.

Although I have not made detailed tests, it appears that Xtol tends to produce an S-shaped characteristic curve with maximum contrast in the midtones (reminiscent of Tri-X Pan, which has this type of curve in any developer), whereas HC-110 and Kodak T-Max Developer produce an "upswept" characteristic curve with relatively high contrast in highlights (dark areas of the negative, light areas of the picture).

You can find development times for many films in Xtol, with measured curve shapes, at FotoImport.no in Norway. The introductory page is in English. The rest of the pages are in Norwegian but you can probably figure out what they say.

The Not-Too-Secret Formula

The material safety data sheet (MSDS) for Xtol describes its ingredients as:Part A: Sodium sulfite Sodium metaborate, tetrahydrate Diethylenetriaminepentaacetic acid pentasodium salt 4-hydroxymethyl-4-methyl-1-phenyl-3-pyrazolidinone Part B: Sodium sulfite Sodium isoascorbate Sodium metabisulfiteHere the pyrazolidinone is one developing agent (a derivative of Phenidone); sodium isoascorbate is the other developing agent; and the others are activators and preservatives.Although the MSDS looks alarming, Xtol is actually a great deal less toxic than other developers.

The origin of Xtol is described in detail in "The Genesis of Xtol," by Dick Dickerson and Silvia Zawadski (Photo Techniques Magazine, Vol. 20, No. 5, 1999, p. 62 ff).

Xtol is covered by U.S. Patent 5,853,964, which gives a formula ("Example 1") that probably corresponds closely to the manufactured product. More information is given in The Film Developing Cookbook, by Stephen G. Anchell and Bill Troop.

If you want to make your own Xtol, see Paul Lewis's Mytol. Patent law permits you to experiment with Xtol-like formulas for your own noncommercial use, but not for sale or for use in commercial photography.