2022

November

28

|

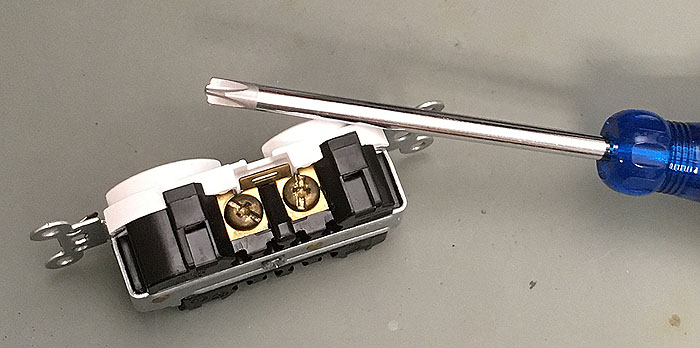

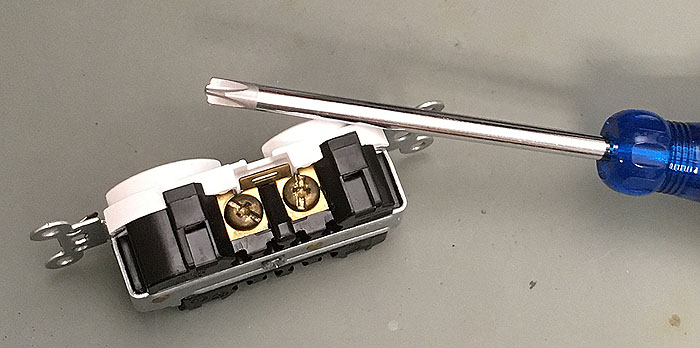

Wonders of technology: Combo-head screwdriver

They invented a screw head for electrical outlets that takes both slot-end

and Phillips screwdrivers.

But it doesn't fit either of those well enough to get the screw really tight,

so next, they invented a special screwdriver that does fit it.

This sounds a bit like painting yourself into a corner and then inventing

a clever escape device that you shouldn't have needed in the first place.

But, actually, the combo screwdriver and screw are nice to work with.

You get the torque of a large slot-end screwdriver and the automatic centering

of a Phillips. And, unlike a Torx, hex, or square drive, it still isn't

too easy to apply excessive torque. It's a good fit to what the human hand

can deliver and the screw and outlet can safely receive.

Permanent link to this entry

Econ-observations

Early reports are that Black Friday shopping was up nicely compared to last year.

But I don't have exact numbers.

If we had the same amount of shopping, but at a price level 8% higher,

wouldn't that show up as an 8% increase? Illusory, of course, but we relied

on such illusions of business growth in the 1970s.

U.S.-China relations seem to be souring, as I thought they might.

I'm glad I took a step to reduce my dependency on Chinese business by

moving to a Losmandy telescope mount.

My iOptron mount is on consignment at Atlanta

Hobby and is a real bargain, especially since it's in better-than-new condition

(and so isn't going to need support from its Chinese manufacturer,

the way a new-out-of-the-box one would). Come one, come all!

I've wondered for some time why Americans, even American conservatives, no longer seem to

disapprove of Chinese communism. It is still an oppressive form of government.

I suppose because everyone was optimistic about increasing freedom in China.

But we need to pay attention to whether they are always moving in the right direction.

Permanent link to this entry

|

2022

November

27

|

Thanksgiving

We had a good Thanksgiving this year. Sharon was able to come along to a gathering at Melody's

mother's house.

Let the record also show that Sharon made dinner for us on Friday — macaroni and cheese with

vegetables and turkey. It was delicious. She is healthier than she has been in years.

Another family member has also had a large bureaucratic problem resolved, which I'll say more

about later; it may have national political consequences. Let me just say that "defunding" a government

agency without reducing its workload is stupid, and when it prevents the government from

paying its just debts or giving out truthful information, it's unethical.

Permanent link to this entry

Post-COVID frenzy

This is the first holiday season in 3 years where we haven't had a high COVID level, and my message

to the world is going to have to be, Please understand I can't do everything everyone thinks of,

nor give everybody the attention they want. Not only are we having a bathroom remodeled, we also

have a pent-up demand for long-delayed medical treatment (I have two things to attend to myself in

the coming month, and

Melody and Sharon are both in frequent physical therapy), and I'm having a busy time at work.

I'm not "retired" and sitting idle, nor can I keep up with people who are. Hang in there!

Permanent link to this entry

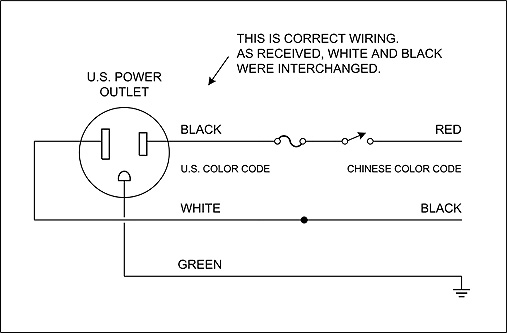

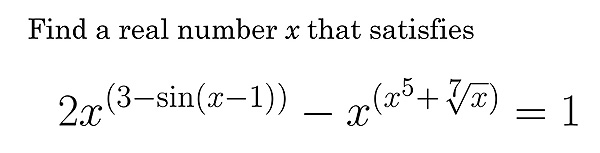

A trick algebra problem

This is much easier than it looks. Click on it to see my YouTube video in

which I explain it.

Permanent link to this entry

Instrumental vs. ethical values

An interesting concept from

Reid Blackman's book on AI ethics:

We need to distinguish ethical from instrumental values.

Ethical values are what's right. Instrumental values help us do what's right.

For instance, justice is an ethical value.

Accountability is an instrumental value — it helps with justice if the people to whom you're accountable want justice.

I think the same applies to fairness and diversity. Diversity is an instrumental value.

Having a variety of people around us helps us be fair to different kinds of people.

But the real goal is fairness, even to people who will never be in our "diversity" because they are rare.

For example, people of Australian Aboriginal ancestry in the USA are not numerous

(I have never knowingly met one in this country), but they certainly deserve fair treatment.

"Diversity" efforts will never bring in very many of them because they just aren't here.

And that is not the measure of success. It's success if, when they do turn up, they are treated as fairly as anyone else.

This is something that has bothered me a little about approaches to race relations in the US for 50 years.

Having a diverse mix of people is good. It gets people accustomed to treating each other fairly.

But the goal is not proportional numbers of faces from each designated group in each room.

The goal is for each person to have the same opportunities and support.

Permanent link to this entry

Video lip sync problems

While making some videos for my grandchildren, I was bitten by a common problem in digital video:

The sound and video were out of sync.

Specifically, the sound was running about 3 frames (3/30 second, i.e., 100 ms) ahead of the picture.

That made it look like my lips weren't matching my speech; sometimes, at the end of a word,

it looked as if I were uttering

another whole syllable that the microphone didn't pick up.

I learned that because of different processing speeds, this happens often in digital video and TV,

and the industry standard allows the sound to run up to 15 ms ahead or 45 ms behind the picture.

I got the worst results with the Windows Camera application; better with Logtech Capture (and my Logitech

webcam); but perfection only with OBS Studio,

which is popular for recording the computer screen but also works very well recording from a camera.

(I had to set custom resolution settings on the camera, because by default, a webcam in OBS Studio

is 640×480, based on the assumption that your talking head will be a small inset into a screen

that is mostly something else.)

While troubleshooting the problem, I used Adobe Premiere to view audio and video tracks together

(DaVinci Resolve and other video editors will do equally well), and I clapped my hands together

as a test signal. Maybe I should get or make a

clap board

like they use in Hollywood; the motive for those is that sound and picture were often recorded

on completely separate equipment that needed to be synchronized at the beginning and end of a scene.

Permanent link to this entry

What's all this live-neutral-earth business?

At an electrical power outlet, the "neutral" conductor is the one that is grounded at the entrance

to the building, and the "live" AC conductor is the other one. There is also a ground wire, for

safety, and in Britain it's called "earth."

More precisely, "neutral" is the grounded center tap of the transformer; there are two "live" phases,

240 volts apart, with neutral halfway between. An American 240-volt outlet has those two "live" phases

as well as (usually) neutral and (always) ground. A British or Australian 240-volt outlet, on the

other hand, is like an American 120-volt one, just with the voltage higher.

As I was saying the other day, a truism of American wiring is that switches

and fuses should be in the live wire, not the neutral. In house wiring, this is no problem.

Inside equipment, it's possible because (since the late 1960s) we've always had "polarized" outlets,

which have either three prongs for live, neutral, and ground, or two prongs of different widths,

neutral wider than live.

The reason for all that is that the wiring inside a piece of equipment might accidentally short

to the case or housing, or anything the user might touch, and then go to the ground either directly

or through the body of a human being who is in contact with something grounded. We want the fuse

to stop this, and the switch also to be able to stop it.

This is something engineers only started caring about in the 1960s; previously, all that mattered

was getting AC power into the equipment. Then they started noticing what happened when things went wrong.

In the U.S., equipment is allowed to have a non-polarized 2-conductor plug only if it is "double insulated,"

which means the AC line is completely insulated from any metallic mechanical parts of the equipment,

screws, switch handles, etc., and also that the case is non-conductive. This is common with power tools

that might need to be used anywhere (including places that might be wired incorrectly).

Now then. Continuing to explore my new soldering equipment, I discovered that,

just like my older Weller EC2000, the new Weller EC1010NA also has no

fuse upstream from its power transformer, and has the switch in the neutral line.

(I can correct the latter by swapping tab connectors around, and I'm planning to do so.)

Both the EC2000 and the EC1010NA do ground the soldering iron itself to the ground wire,

and they have everything else well insulated from it; basically they are double-insulated and

then grounded.

How concerned should I be? Well, I think the EC1010NA needs a fuse upstream of everything else.

Maybe its transformer is the fuse — is designed to burn out non-destructively —

and Dave Jones' accident

was an instance of it freakishly failing to do so. There is certainly a fuse on the output of the

transformer, which protects against any short except one inside the transformer itself.

Continuing to ask about this, I've concluded that "double-insulated plus ground" is the only reasonable

way to build things, because there's so much variation in practice.

That is, ground the case (and soldering iron tip, or other mechanical parts) to the ground wire,

but make no assumptions about live and neutral, because they are so likely to be swapped!

I found plenty of reports of North American IEC power cords that swap live and neutral.

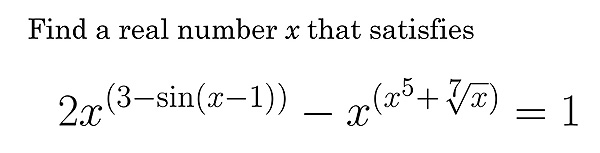

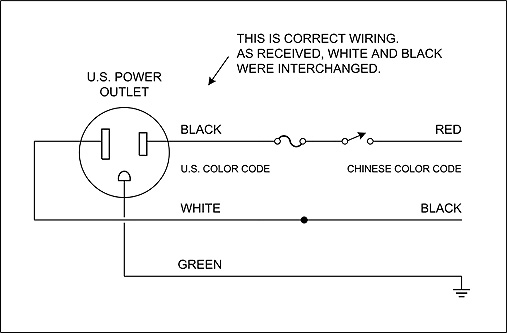

Here is how they are supposed to be (red marks live):

I also learned that outside North America, Britain, Australia, and a few other places,

all bets are off. In Germany and Scandinavia, for example, you have 240 volts with live, neutral, and ground,

but it's unpredictable which is live and which is neutral; sometimes the 3-wire plug can be put into

the outlet either way, with the ground connection on the edge of it.

(This has to be seen to be believed.)

A few places in Italy supply 240 volts as 2 live wires on opposite phases (like an American 240-volt outlet),

with no neutral.

In the Philippines, 120-volt and 240-volt outlets both exist and may take the same plugs.

And Brits on construction sites often use 110-volt tools (probably double-insulated ones built for North America)

supplied with two opposite 55-volt phases, with neutral in the middle

(actually a good idea, because a 55-volt shock is much less likely to cause injury;

maybe we should do that here).

In short, it's a wild world out there!

So maybe Weller is off the hook because they are a German company — live and neutral are

unpredictable to them. But I still think it would be better to follow the British/American

practice, knowing that in some parts of the world it doesn't make a difference.

Permanent link to this entry

|

2022

November

20

|

Keyhole saw

This keyhole saw will do productive work today for perhaps the first time in 80 years.

My father gave it to me when I was 8 years old, during construction of our house

at 1103 Lake Drive, Valdosta. I was not able to use it; it seemed dull, it was bent,

and the wood scraps I had to play with were very hard (pieces of 2×4 and 2×6

yellow pine framing lumber).

It got packed up, and, at one point, almost lost, when it was given to Melody's grandfather

(a professional saw-sharpener) to fix up in the early 1990s, and then he died before getting to it.

But it was retrieved and has hung on my pegboard ever since.

This saw was old when I got it in 1965. I think it was used in the construction of my

grandparents' Jenkins County farmhouse in the early 1930s, when my father was a boy.

In those days a keyhole was a 3-inch-square opening for a lockset, and the name of the

saw made more sense.

Last night I spent some time getting the bends out of it, as well as removing rust.

It is good enough to use now (and isn't bad as regards sharpness), and today or tomorrow,

I'm going to use it to cut a hole in sheetrock for a new outlet.

[This was finally done on November 26, and the saw worked well.]

Then it will probably go back up on the pegboard and continue to hang in a place of honor.

Permanent link to this entry

Sundry workshop notes

KiCad 6 on high-DPI displays:

Somewhere between version 6.0.0 and 6.0.9, KiCad updated its GUI and did something that requires

intervention if you use a high-DPI display.

Click here for similar information applying to other software.

Then, for KiCad 6, go to C:\Program Files\KiCad\6.0\bin and perform that intervention

for eeschema.exe, gerbview.exe, kicad.exe, pcbnew.exe, and pl_editor.exe.

Hallicrafters S-40B hint:

I know I'm not the only person in the world still using a Hallicrafters S-40B shortwave radio

(mine was my father's, and I've done a lot of work restoring it).

Well, here is one more hint: Replace the 6SG7 tube (RF preamp) with a 717A,

a special military tube that gives higher sensitivity, especially at higher frequencies.

I finally got around to doing that, and for the first time ever, Band 4 works well.

The whole radio is working better and does not seem to need realignment.

I want to thank the person who told me about this and sold me the 717A several years ago;

I don't remember who it was. My 717A is old, but it looks like 717As are still being made for tube

audio gear — and sold for high prices!

Flux removal controversy:

For many decades, the standard advice about soldering in electronics is that afterward, the flux needs

to be removed with isopropyl alcohol, or it can cause problems later.

But wait a minute. Current Kester data sheets such as this one

say:

All the data sheets say that — not only for the newer "no-clean" fluxes, but even for Kester 44,

the 60-year-old standard product, whose sheet I'm actually quoting.

(This doesn't keep me from wondering whether Kester has accidentally copied text from another product,

though.)

What gives? Looking around YouTube, where people often demonstrate their shop technique, I've

gleaned the following (but not done my own experiments):

-

Many maintain that isopropyl alcohol does work, but you have to use a brush or cotton swab.

After all, the goal is to remove the flux, not just redistribute it.

-

Some of the flux removers on the market are chemically exotic alkaline saponifiers,

but most are basically

lighter fluid (hexane) in a spray can. Very flammable!

I'm reluctant to use more than just one quick squirt indoors (away from electrical

equipment).

-

I don't think I actually need to buy flux remover;

CRC QD Electronic Cleaner (from the local hardware store)

seems to work well. It also is basically lighter fluid in a can.

-

These hydrocarbons are much more flammable than isopropyl alcohol,

but alcohol is flammable too. We have to be careful.

-

Regardless of the solvent, rolling a cotton swab is particularly recommended.

After all, you're trying to pick up the flux.

-

Reportedly, warming the flux with hot air makes it much easier to remove.

(Careful! Keep flammable solvents away from heat sources!)

Obviously, there's more to learn about this, and I don't think the industry as a whole

has reached a consensus yet.

Permanent link to this entry

|

2022

November

19

|

New soldering equipment at Covington Innovations

Further to my desoldering endeavors the other day (which were unimportant, but could

prefigure something I might really need to do to repair something),

I realized that a 39-year-old, 40-watt soldering iron was probably not really adequate.

In the 1970s, we moved toward tiny soldering irons (as little as 10 watts) to avoid

overheating delicate semiconductors and printed circuit boards.

Then we realized that it is often easier to overheat things with a low-power iron than

a higher-power one, because you hold the heat on them longer.

(Analogous it to being easier to cut yourself with a dull knife than a sharp one.)

Temperature-controlled irons came in, and

we found higher power beneficial; the iron delivers no more power than needed,

but the ability to kick up to a higher wattage automatically is handy.

For a long time I have been using a 1980s-vintage

Weller EC2000 that I picked up secondhand and fixed up

(some details here; I had already had it for years before that).

Note the December 1983 manufacture date that was stamped in it.

It was still working fine, but I thought the heat conduction to the tip might have

degraded, and besides, it's only a 40-watt iron, not always adequate for quick work on

multilayer boards.

So I bought its successor, the Weller WE1010NA:

[Amazon picture. Click on picture for Amazon link.]

This is a 70-watt iron that takes the same ET-series tips (which I had plenty of) and has better

digital controls, as well as the ability to shut off after a period of disuse.

As this review reveals, if its temperature seems to vary a lot, that's

because it's more effectively measuring the temperature of the tip, not the heating element.

I also bought an amazingly low-priced Chinese-made hot-air rework station, a Yihua 959D, and

did a safety checkout of it (see next entry) and found a modification to be needed.

Permanent link to this entry

Safety checkout and repair of Yihua 959D hot-air rework station

(See also this thread on EEVBLOG Forums.)

Nowadays an electronics lab needs not only a soldering iron, but also a hot-air rework station.

That's a gadget that blows air hot enough to melt solder, but at a limited temperature so it doesn't

melt everything in its path. I chose the Yihua 959D, available from Amazon:

[Amazon picture. Click on picture for Amazon link.]

This review of a similar, earlier model leads to the same

conclusion I reached: These gadgets are well designed but not always well assembled.

Apparently, the same products from the same factories are marketed under different brand names,

and Yihua is one of the most prominent and most concerned with quality control.

There have been horror stories,

so I was determined to give this one a thorough safety check before using it much.

Based on many discussions I found and reviews on YouTube (of many related models, not just this one), here are the things I checked:

- Air intake holes in the handle are not blocked (somebody got one where they weren't completely

open because of poor plastic molding). (PASSED.)

- Magnetic reed switch inside handle is well secured in place. (PASSED.)

- Fuse and on-off switch turn off all incoming electric power. (There is talk of a model that could

turn itself on, via a shorted semiconductor, even when switched off. I have not absolutely confirmed this.)

(PASSED.)

- Metal tip is wired to the ground pin of the power line plug. (PASSED.)

- Fuse and on-off switch are wired to the live (hot) side of the power line, not the neutral side. (FAILED.)

- When turned on and used, the device performs generally as specified. (PASSED.)

Oops! Despite getting a generally good bill of health, this hot-air station did require a repair right

out of the box, and it's something a user would never have noticed, because it didn't keep it from operating

normally, but would make it less safe if certain kinds of short circuits accidentally arose.

It's supposed to be wired this way:

I found live and neutral interchanged. I think the assemblers were misled by the difference between

American and Chinese color codes — black is live in North America (but nowhere else!) and black

is neutral in the old British color code, still used in China. (Live is brown and neutral is blue in

the new international color code.) Recall that I actually found the same error in my old Weller EC2000,

although I don't know if it was Weller's error or a later repair technician's.

I swapped the wires, and it now works entirely as specified.

For additional safety, I also arranged for all the soldering equipment in my shop to be on a

switchable power strip, which also powers the fume extractor (whose own switch is taped "on")

and a small light. That way I can't walk away from the shop thinking the soldering equipment

is all turned off when it isn't. And I'm installing a GFCI upstream from it.

What are we to make of the horror stories?

Particularly the one in the video to which I linked?

I don't know. This is a 700-watt device, and there is always the chance that its controls could

fail and it could get very hot.

Apparently, the man in the horror story experienced a rather unlikely combination of failures.

(In mine, a shorted triac alone wouldn't do it; there's also a relay.)

But unless his station is wired quite differently from mine, he still could have just flipped

the power switch to turn it off.

The moral? Stay with it and watch it while it's on. That applies to all power tools,

actually.

Permanent link to this entry

|

2022

November

13

|

5 GHz is a different world

Today, an electronics workshop note.

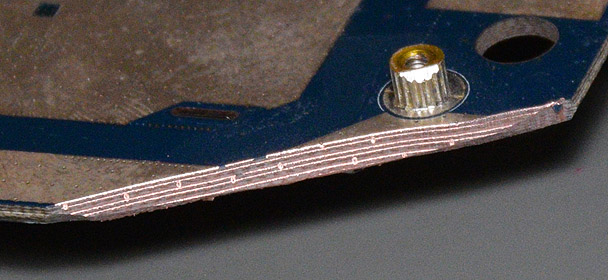

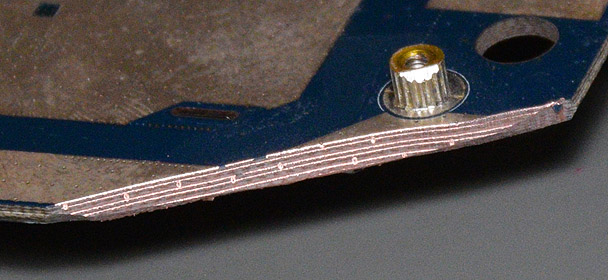

I was having undue trouble desoldering some through-hole components that I was salvaging

from the circuit board a defunct Wi-Fi router.

The solder just wouldn't melt all the way through the holes, even with a 40-watt iron.

Eventually I made the board give up its secret.

I ground away a corner at an angle to see the layers.

Look at all that metal!

This is at least a 6-layer board, and, for shielding, the copper was apparently left

in place almost everywhere on all the inner layers.

In fact, there's no way it could have needed 6 layers for connections;

almost all of the layers must have been solid copper, with occasional holes

where something needed to go through, but serving as a shield and ground plane.

The abundant copper carried away the heat from the iron and made desoldering impossible.

The board was originally soldered in a reflow oven that heated everything at once.

A more sophisticated desoldering technique, for what I was doing, is to heat the whole

board on a hot plate — not hot enough to melt solder, but close — and then

apply the soldering iron where it's needed. Then it only has to make maybe a 100-degree rise

(Celsius) instead of a 300-degree rise, and it works as expected.

Permanent link to this entry

|

2022

November

12

|

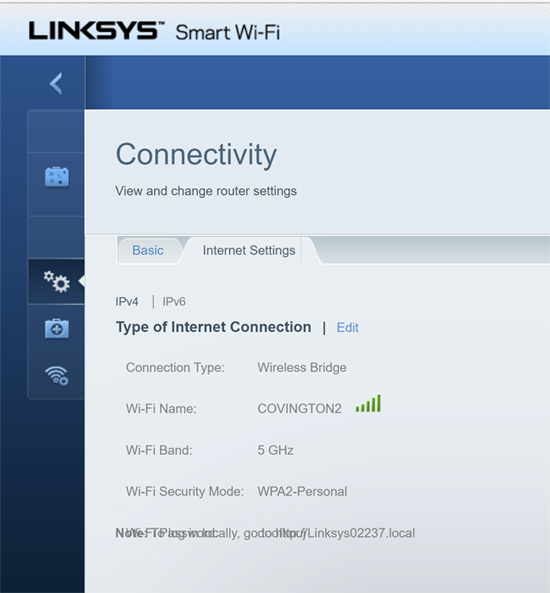

Setting up a Linksys router as a wireless bridge

(range extender)

I just bought a couple of new Linksys MR7350 routers to extend my home network,

using one as a wired bridge and the other as a wireless bridge

(an additional access point that connects to my main router wirelessly).

I had absolutely no luck with the semi-automatic setup app that runs on my smartphone.

It connected to the new routers, argued with them, and didn't get them configured.

So I did the configuration manually, using the router's own menus.

Cutting to the chase: You must have a WIRED connection to the new Linksys router

at the moment you are putting it into Wireless Bridge or Wireless Repeater mode. If you're

talking to it wirelessly, it will seem to work, but the settings just won't stick.

I think this is a firmware bug, but in that situation it will not have had any

chance to update its firmware.

Here's the whole process I followed.

(0) Hint: To return a Linksys router to factory settings, hold down the RESET

button for 20 seconds (while it's powered on, of course).

(1) Make a WIRED connection by Ethernet cable from a computer to one of the numbered

ports on the new router (not the "Internet" port). Linksys supplies a short Ethernet

cable for the purpose.

(2) Connect your computer to that wired connection (probably "Unknown Network") and

disconnect from all other networks, wired or wireless.

(3) Type 192.168.1.1 in the address bar of your browser.

(Every router is 192.168.1.1 until something else gives it a different address.

Don't get confused; on your network, your main router is 192.168.1.1;

but when connected directly by wire, any new router you're setting up is 192.168.1.1.)

(4) You will see a screen telling you to get the smartphone app.

Don't. Just click on the picture of the phone, and you'll get to the password prompt

("Access router" or "Access Velop").

(5) If you have not set it otherwise, or if you have reset the router, the password is admin.

If the router is going to be on a secured network and none of the network users have any reason

to tamper with it, I don't think you need to set a different password.

(6) Now you'll get to the main menu, which is a set of white panels on a dark blue

background.

(5) Hint: At the extreme lower right of the main menu, you can click on the

tiny letters "CA" to unlock additional menus. In this situation I did not find that

necessary, but it gives you more settings.

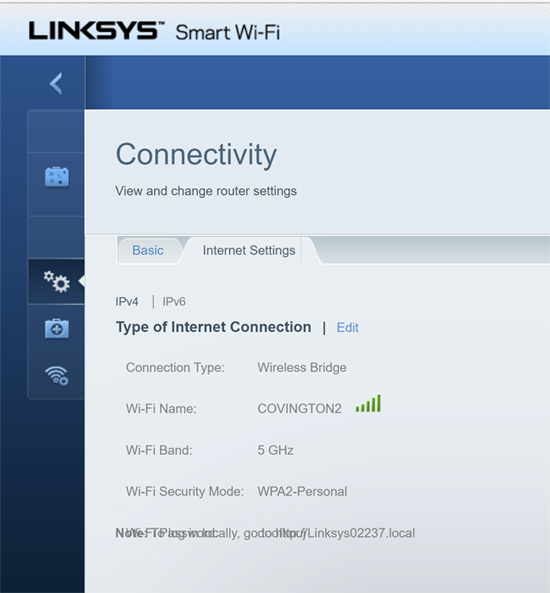

(6) In the menu on the left side of the window, choose Connectivity, then Internet Settings, Edit,

and set the connection type to Wireless Bridge.

(7) (Important!) Fill in the Wi-Fi name and password for connecting to your existing network.

You will need to choose Security = WPA2-Personal in order to be prompted for the password.

Then, if you encounter the same firmware bug that I encountered, there will be writing across the

box where you are supposed to the the password (see picture above). You cannot click in this box,

but you can get to it by pressing Tab a couple of times.

(8) Click Apply.

(9) Back out and go to Wi-Fi Settings and put in the network name and password you want

to use for this access point (they can be the same as for your main network). Click Apply.

(10) Now you have a wireless bridge that will connect to your main router. You can remove the wired

connection and connect to the new wireless bridge wirelessely; it will be an access point on your main

network.

(11) Next task is to arrange a convenient way to get to the new wireless bridge's menus so you can make

further settings when you want to. While connected wirelessly, go to 192.168.1.1 in your browser.

This time it will be your main router. If it's a Linksys, then log into it and go to Device List.

There you can see all the connected devices and find out the address that has been assigned to the

new wireless bridge, something like 128.192.1.XXX where XXX is an unpredictable number.

(12) If you wish, you can go to that number in your browser, and get to the menus of the wireless bridge.

But the number will change unpredictably in the future.

(13) What I did, on my main router (192.168.1.1 on the main network), was to do two things:

-

In Connectivity, Local Network, set the starting IP address to be 192.168.1.2, not 1.10.

-

Click on DHCP Reservations, find your new bridge, and assign it 192.168.1.2 (or 3, or 4, if you

have several of them.

-

Power-cycle the new bridge and wait a few minutes.

Now the bridge will be 192.168.1.2 on the main network, and you can get to its menus at any time.

Permanent link to this entry

|

2022

November

11

|

Are we in a different era now?

[Slightly revised.]

In the past three or four days, several surprising things happened.

- We got through our midterm elections with no violence, no major disruption,

and (so far) not even any strident claims that the results were "stolen."

- Trump's promised "red wave" did not happen.

There were modest Republican gains, but largely by candidates not closely

associated with Trump.

-

Russia retreated out of some occupied Ukrainian territory.

- The stock market rose about 5% yesterday (leveling off today as far as I can see),

and, surprisingly, 30-year mortgage rates fell from 7.2% to 6.6% without Fed action

[according to a news report; I have not confirmed this on sites that publish charts].

This was in response to inflation data showing a less-than-expected rise in prices,

but not a fall, which would have betokened a recession.

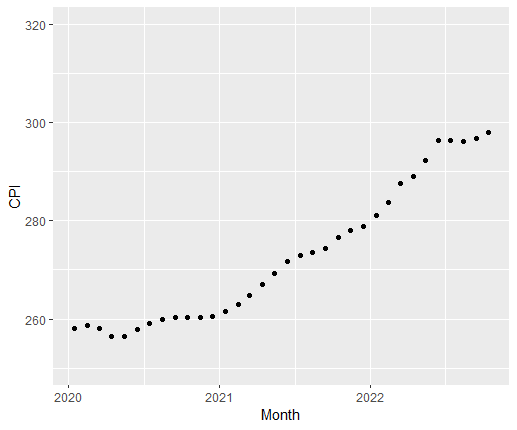

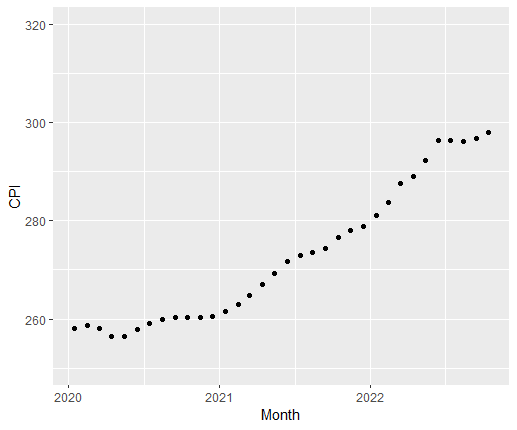

First, the inflation chart. I'm going to maintain this chart monthly, so here it is with

one more dot than last month, and done this time with ggplot2:

Not soaring inflation, but not flat either. Does this justify the sudden change in national mood?

I think the stock market gains are actually a response to something else:

the Trump era is over, and with it, perhaps, the constant demands to

deny reality and believe absurd things.

I make a big distinction between supporting a conservative platform and joining a

personality cult. I don't fault the people who voted for Trump because they thought

that, even with his peculiarities, he was still a safer choice than the alternative.

But I have lost friends who swallowed propaganda from extremist movements,

who believed Trump was God's Anointed, and who wouldn't let go of him no matter what strange

things he did. He is now in serious legal trouble on many fronts, the biggest

involving secret stashing of secret documents at Mar-a-Lago, and there is much

less political pressure to let him get away with things than there was a few days ago.

And he says strange

things. He has just been quoted as saying the country would be better off if he still

had the nuclear launch codes. Is that a madman's threat of violence against the whole world?

If not, he certainly has some explaining to do.

Today the Wall Street Journal calls him the Republican Party's biggest loser.

I do think his heyday is over.

Permanent link to this entry

Some thoughts about elections

[Previously posted on Facebook.]

(1) Have you noticed that in recent years, we've had a lot of VERY CLOSE elections? I think this is due to scientific polling and campaigning; everybody wants to spend just enough to get 50.001% of the vote. As a result, election returns are cliffhangers, and even the smallest risk of election irregularities is a serious hazard. I would like to see candidates go back to trying to win by a large margin.

(2) When I was young, a widespread tactic was to campaign with a moderate platform and try to attract undecided voters. Remember Nixon and Humphrey, for example?

(3) Recently the tactic has shifted to a much less congenial one: Adopt an extreme position and tell the undecideds that your extreme is better than the other extreme. This leads to both sides calling each other evil and being unwilling to work together. It is not a good thing.

(4) My fellow Christians, in particular, need to get their heads clear. I don't remember anybody claiming that either Nixon or Humphrey was God's anointed. Contrast that to later years. We are not the Chosen People anointing Solomon king. We need to stop letting candidates and parties co-opt us. We Christians should be a hard sell for everybody; we should support candidates only weakly and be ready to ask all of them to do things better. So should all rational people, whether or not they are Christians.

Permanent link to this entry

|

2022

November

4

|

Jupiter and Saturn

I know there hasn't been a Notebook entry since October 22.

Don't worry; we're just busy. One of the things we are busiest with

is getting the master bathroom remodeled.

But I have gotten some astrophotography done.

Each of these is a stack of the best 25% to 50% of thousands of

video frames, taken with my Celestron 8 EdgeHD, a 2× focal extender,

and an ASI120MC-S camera. The first Jupiter picture was taken with

the telescope riding on my AVX mount to give it some exercise;

the latter set of pictures were taken using the Losmandy mount, whose

square-spiral search feature is very useful if Jupiter or Saturn fails to

land precisely on the tiny sensor of the camera.

Permanent link to this entry

A pre-election thought

[From a posting of mine on Facebook.]

I think this country has been harmed by too much enthusiasm for political candidates. The rational voter's attitude should normally be, "I'll vote for you because you're a little better than the other one, but I'll immediately start prodding you to do some things differently." Politics should not be like cheering for a football team. You do not owe "loyalty" to "your" candidate!

Permanent link to this entry

Another pre-election thought

Some people seem unable to disbelieve any words that happen to be running around in their heads.

Politicians are trying to exploit this failing right now.

True means true in the real world, not true in some words that you heard.

The ability to taste an idea without swallowing it is vital.

Permanent link to this entry

|